GREEN RETARDER

Technical specification for the rail holding, safe shunting and speed device

GREEN RETARDER

The Green Retarder was preceded by the VH Retarder, designed and patented by the same inventor. The story of the Green Retarder is interwoven with one of the most challenging problems facing the rail transport industries: that of routing a multitude of rail wagons to various destinations in the most effective and efficient manner, without sacrificing safety and predictability.

Over the last five years, the Green Retarder has been developed to the same exacting standards as the VH Retarder, in answer to the challenge of new, friendlier Ecology requirements in international law, and tested over 10 000 hours and 50 000 wagon transfers. Other significant improvements have been brought to the Green Retarder, in the following regards:

- Fewer moving parts.

- Less maintenance.

- Each unit can be individually adjusted.

- The unit operates on Pneumatics, not Hydraulics.

- The system can be integrated electronically with the Signal System and remotely controlled.

- The System can be deployed on an ad hocbasis, as opposed to full-time deployment.

- The piston is in the default down position,not default up, resulting in substantially less wear and tear during idling onboth the Retarders and the Wagon Wheels.

GREEN RETARDER

Variation in power extraction, Reduce maintenance (less parts), Full control of retarders, Link retarders to signals, Less setting up time, No loss charges less chance of unplanned acceleration.

THE ENVIRONMENTAL STEP

NO OIL HENCE

NO OIL SPILL

NO NITROGEN USE

NO LOSS CHARGE

NO DERAILMENTS ON TRAIN EXIT

RETARDER FUNCTIONS

Designed to hold trucks once uncoupled from the locomotive.

The retarders are able to slow down trucks entering in a controlled area.

Manufactured to ISO 9000 and ISO 14000 standards

Manufactured using only rolled or forged high quality carbon grade steel, with all precision machining, using CNC machines, purpose engineered for this product.

The product is manufactured and exclusively developed for the railroad, and marketed internationally by Gravity Engineering.

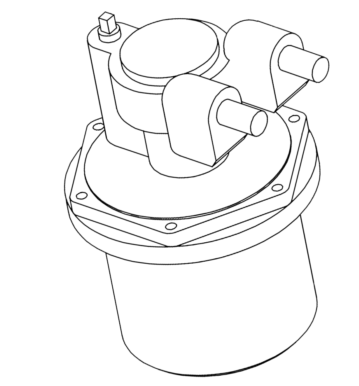

Main Components

• Air compressor – reciprocating compressor, air-cooled, splash lubricated, belt driven, special high resistance cast iron construction, for industrial applications

• Constant Speed Control – The compressor switches to unload service when receiver pressure reaches the pre-set unload pressure, and the absorbed power is reduced to about 1/5, with the motor always on.

An Environmental Step Forward

Hydraulic oil has been replaced as a compressing medium in the new design with a pneumatic system.

No oil spillage will prevent damage to the environment and prevent poisoning the ambient groundwater.

Nitrogen has been replaced as a recharging medium in the new design with compressed air.

Risk of charge failure, with resultant damage to property, injuries and casualties to persons have been eliminated.

Operational Safety and Maintenance Improvements

Wagons can no longer be derailed by the retarders.

can be easily set on site to optimum effectiveness.

Risk of loss of charge is eliminated, obviating unplanned acceleration due to gravitational momentum. in tandem with uncharged retarders on the line.

Parts have been reduced, making maintenance easier.

Variable shock absorption is now achievable.

Retarders can now be linked with signals, and turned off when the train leaves the siding/ marshalling yard.

Wear and tear on retarders and wagons is thus reduced by more than 50%.